Do you opt for organic produce and natural cleaning products? If you’ve already thought about embracing more sustainable and natural materials in your home environment, then you'll want to know about this neat, plant-based material. Enter natural latex.

Natural latex is steadily growing in popularity as an alternative to synthetic petroleum-based products, known more specifically as poly foam or memory foam, which is commonly used for furniture cushions and mattresses. Natural latex is a plant-based material: one of the most durable and resilient foam materials you can find, and offers a truly eco-friendly alternative to conventional petroleum-based furniture. Let's dive into what it actually is and what makes it so special.

What is natural latex?

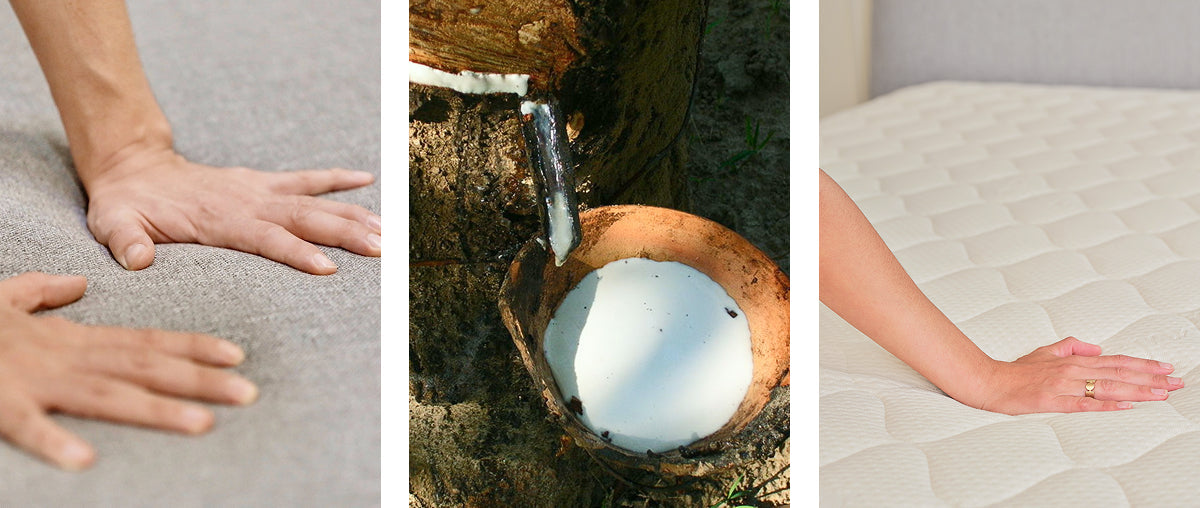

We know the word "latex" sounds plasticky and evokes visions of the dentist snapping gloves on before your procedure, but natural latex is actually quite beautiful: a white, milky substance sustainably harvested from the sap of rubber trees (Hevea Brasiliensis). Synthetic latex can also be produced artificially via chemical processes, but we’ll get into this a bit more later. It’s important to note that “latex” can refer to both the artificially produced synthetic latex (think blue rubber gloves) or plant-based natural latex (the kind we use in our furniture).

Where does natural latex come from, and how is it harvested?

Harvesting natural latex is simple and typically requires no harsh chemicals, fertilizers, or pesticides. It takes about seven to ten years of growth before rubber trees produce sufficient amounts of latex, a waiting period that ensures new rubber trees are planted continuously.

Latex is harvested from rubber trees by "tapping" them, just like maple syrup. This method involves a latex harvester making shallow cuts in the tree bark to release the milky sap, which drips into a collection cup. This process allows the tree to produce latex for decades, with new cuts made as old ones heal. Super cool!

After about 25 years, rubber trees stop producing the sap needed to make latex and are often harvested for wood. Since the wood resembles teak, the wood can be used to make furniture, and is also commonly used in timber and beam construction.

How is natural latex foam produced?: Dunlop vs. Talalay

The process to create natural latex is made in one of two ways: Dunlop or Talalay. The biggest difference between the two is that Dunlop latex is more durable and long-lasting (and great for sofa cushions here at Medley). Let’s dive into the detailed differences between Dunlop and Talalay processing:

The Dunlop process:

- Liquid latex extract is whipped into a frothy foam.

- The mixture is then poured into a mold and transferred to a vulcanization oven. To give latex its final shape, the vulcanization process engages sulphur, an agent that helps initiate the vulcanization, and zinc oxide, which helps prevent the foam from oxidizing.

- The latex is then washed, helping retain elasticity and counter aging.

The Talalay process:

- Liquid latex extract is whipped into a frothy foam.

- Liquid rubber extract is inserted into a closed mold that is vacuum-sealed.

- The mold is then frozen to permit stabilization of the latex.

- Carbon dioxide gas is then added.

- The mold is baked to cure the rubber.

- Once vulcanization has occurred, the latex is de-molded and sent for washing and drying.

Natural vs. Organic vs. Synthetic Latex: What's the real difference?

Remember how we said that “latex” can refer to both natural and synthetic latex? If you’re looking for the most natural and sustainable option, it’s important to understand what to weed out.

Natural latex is made from rubber tree sap and does not typically involve added fillers. However, natural latex that is not certified organic can contain a blend of natural and synthetic components and possibly might have small amounts of residual chemicals or pesticides due to the processing chemicals sometimes used.

Organic natural latex is harvested and processed under strict guidelines, and is guaranteed to be free from synthetic chemicals, pesticides, and herbicides. This type of natural latex must be certified by a third party, the most prominent being the Global Organic Latex Standard (GOLS), which verifies organic farming, chemical-free processing, fair trade, and appropriate wastewater treatment.

To label latex as GOLS certified, it must contain a minimum of 95% certified organic raw material of the total weight (raw materials in the product must comply with the requirements on organic origin). In our case, the 3-5% left over accounts for approved, essential processing additives required for any manufacturer to make natural latex foam suitable for home furnishings — additives are mostly comprised of sulfur and zinc oxide, which help initiate vulcanization (turn latex from a liquid to a solid via heat) and protect latex from early oxidation.

TLDR: All organic latex is natural, but not all natural latex is organic, meaning organic versions guarantee no pesticides, synthetic chemicals, or harmful processing, and offer the highest eco-friendly and purity standard. To make sure you’re opting for organic latex, look for a GOLS certification. Without it, it’s hard to prove whether the latex is certified organic rather than mixed with fillers or synthetics.

Synthetic latex is manufactured by mixing natural latex from rubber trees with a petroleum-based plasticizer. Typically, butadiene or styrene is used as the mixing agent. As a result of the added chemicals, synthetic latex is not considered natural.

Synthetic latex is manufactured by mixing natural latex from rubber trees with a petroleum-based plasticizer. Typically, butadiene or styrene is used as the mixing agent. As a result of the added chemicals, synthetic latex is not considered natural.

Blended latex is made by combining synthetic and organic latex and may also contain other fillers to balance the feel of latex with cost.

How to tell if natural latex is natural or synthetic?

A latex expert can rely on their professional knowledge and tell the difference between natural and synthetic latex through sight, weight, and feel. Natural latex is significantly heavier and softer than synthetic latex. Additionally, natural latex offers resilient support and softness while synthetic latex can be airier and less durable.

For most people, however, the only way to be certain you have a quality foam is to rely on third-party certifications like GOLS for authenticity. Look for this label to verify purity and lack of harmful chemicals.

Natural latex comfort: What does it feel like?

Natural latex foam offers a unique combination of density and softness with a gentle bounce. The result is a cushiony, supportive lounge that's exceptionally comfortable. Latex makes a wonderful material to sit or sleep on: its rubber properties allow the material to contour to your body, offering responsive, gentle, and pressure-free support. It also naturally absorbs motion, setting you up for a smooth, bounce-free lounge or snooze (one reason why natural latex mattresses knock it out of the park).

Is natural latex durable?

Natural latex foam's inherent spring-back properties means that it resists impressions from use over time and can maintain its shape for 20+ years (!) compared to poly foam’s 10 year claim. Bonus points: it's also naturally resistant to mold, mildew, and dust mites and, unlike many other types of foam, does not absorb moisture or heat. All of this means that natural latex foam stands up to wear and tear better than conventional poly or memory foams, and that a latex mattress or cushions are the most likely to resist sagging over time.

Natural latex and your health

When you opt for a natural latex sofa, you need to worry less about harsh chemicals or high levels of off-gassing than you would with a traditional synthetic cushion filling made from poly foam. Sofas and mattresses made of traditional petroleum-based foam typically off-gas volatile organic compounds (VOCs) and other harmful substances like ozone depleters, heavy metals, and added flame retardants. Because organic natural latex is made from rubber tree sap, it's petroleum-free and doesn't emit harmful VOCs.

All in all, organic natural latex foam is more eco-friendly, durable, and sustainable. And yes, it is c-o-m-f-y: once you've experienced sleeping or lounging on organic latex foam, there's no going back.

Is natural latex okay for latex allergies?

If you are allergic to latex through a skin allergy, you should be safe to live with Medley products. While there are varying latex allergies out there, the most common is an allergic reaction to the sap proteins from rubber trees via skin contact with latex products. Since Medley’s organic natural latex is wrapped in wool, cotton, and then fabric, there won't be any direct skin contact with the latex cushion.

Some people have a respiratory allergic reaction to natural latex through breathing in latex particles, but this is rare. If you have a respiratory latex allergy, we recommend you consult with your doctor. As always, it’s best to discuss all health concerns with your medical provider, but we're happy to share all the details to help you feel confident in your choice: more about our natural latex below!

Medley’s natural latex: certifications, lifespan, comfort and more

Medley’s latex is certified organic by the Global Organic Latex Standard (GOLS), the gold standard of the industry that indicates purity of material, fair labor practices, and eco-friendly processing.

Natural latex naturally maintains its shape and resists impressions from use over time, so you can count on your sofas, sectionals, and mattresses to last for the long-haul – our GOLS-certified natural latex can hold its shape for 20+ years. We also offer a 10-year warranty on cushion cores against manufacturing defects and significant loss of shape or resiliency, and a 20-year warranty on our ultra-durable Organic Latex Mattress. For an added bonus, Medley offers an industry-leading lifetime warranty on all furniture frames, including all internal springs and wood structural elements, against cracking, breaking, or warping.

For ultimate comfort, at Medley we wrap every latex cushion in an envelope of OEKO-TEX Standard 100 certified cushy wool fiber for extra softness and squish; we also pad sofa arms and backs with latex for all-over softness and squish. You can always find more details on our Craftsmanship and Materials pages.

The Bottom Line

If you're ready to make a more sustainable, health-conscious choice for your home, certified, organic, natural latex is worth the consideration. From its eco-friendly origins to its outstanding lifespan, this cool material offers a winning combo of comfort, durability, and environmental perks that synthetic foams just can’t beat.

Whether you’re looking to invest in a natural latex mattress, sofa, or sectional, choosing GOLS-certified organic natural latex means you're saying yes to healthier, comfier lounging and no to harmful off-gassing. Once you've tried the plush, responsive comfort of organic natural latex, you'll wonder why you ever settled for anything else.

Shop organic natural latex mattress

Shop organic natural latex mattress sofas

Shop organic natural latex mattress sectionals